Realization of the prototypes

The created prototypes are far from being perfect. It was necessary to make as well as possible according to my means of realization,

the time I got to do it and the cost of materials.

That avoids me to realize all the evolutions I had in mind ; Because after having taken certain choises, it would have be necessary to

start again from the beginning to take in account more improvements.

The body :

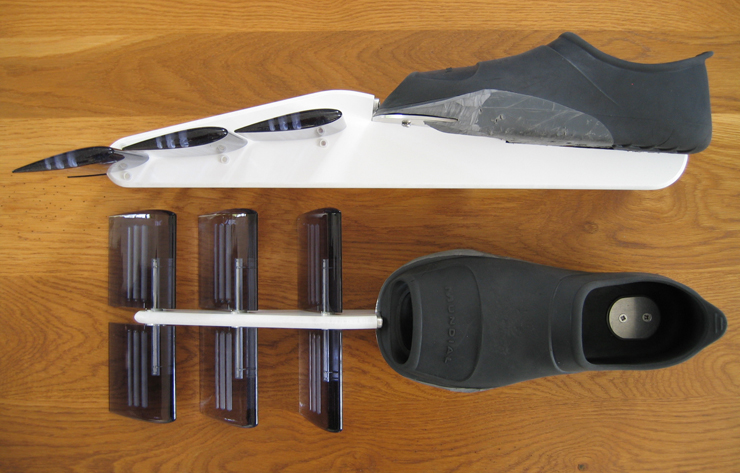

Its overall length is of 54cm for 19cm of width, and its weight is of 1150gr (of which 450gr only for the slipper). Its apparent weight

(weight - pushed of Archimedes) is of 160gr (of which 80gr for the slipper !).

It consists of a slipper recovered on an old fin on which was fixed an aluminum plate. This plate is screwed with a body in

extruded PVC of 10mm thickness.

The body is prolonged to the heel of the slipper to have a better rigidity. Indeed, during the tests of the first two prototypes, the slipper

became deformed too much. A good rigidity is important to allow a faster phase shift of the wings.

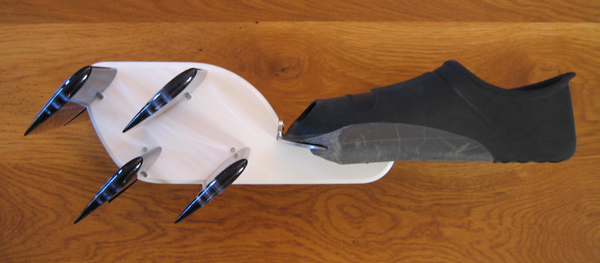

Another type of body was created in optics to benefit the maximum of the part nearest of the foot (more profitable mechanically).

It is about a body with 2x2 pair of superimposed wings, as you can see it on the following photograph. But the turbulences due to the slipper,

added to the disturbances that the wings are inflicted mutually, did not allow to carry out conclusive tests. It would be necessary to test the

principle further more, with a shaped slipper and by spacing more the wings from one to each other.

The wings :

There dimensions are : 76mm length of cord, 90mm wide and a little more than 12mm thick.

They are carried out, by casting, with epoxy resin. Their profile is of type NACA0016 so that their thickness is sufficient

to accommodate the axis. The resistance of the resin being quite higher than my waitings, that enabled me to change the type of attachment on the axis.

Envisaged in the beginning to be stuck, the axis will be finally free in rotation in a hole of the wing.

the resin used having a density of 1.1, it was necessary to create air pockets in order to lower it around 1. Indeed,

if the wings are too dense, or not enough, they can take unexpected positions at very low speed. But at full speed, it is less important.

Propelling bodies :

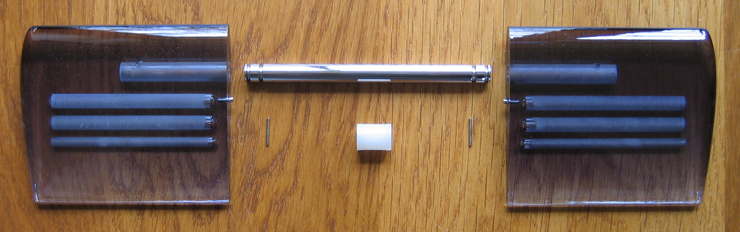

They consist of a pair of wings fixed at an axis.

The axis is a stainless tube of 8mm of diameter for 1,5mm thickness. A groove of one millimetre of depth was carried out on each end to be able

to fix the wings on it. (on the photograph, we see 4 grooves and not 2 because the body of the first prototype was 20mm wide instead of 10mm, it was thus necessary to

readjust the site of the grooves.)

The element which connects the propelling element to the body is a nylon tube (visible at the center of the photograph).

The internal diameter is 8mm, the length is 14mm and is inserted in force in the body.

A contracting of its external diameter was operated on 10mm in its medium. Thus, once in position and that the axis is inside, it cannot leave any more.

The wings are fixed at the axis using a small stainless stem. This one is inserted in a small hole of the wing when the groove faces the

axis . Thus they can turn freely without leaving.

The site of the hole intended to receive the axis is very important. It is placed here on the cord, at 20mm from the front of the wing (leading edge).

It is thus roughly 1mm behind center of pressure. Many tests are to be made on this side because that influences directly

the slope of the wings.

The following photograph makes it possible to see better this attachment unit:

On this photograph we can also see the thrust system which prevents the wings from being turned over. They are aluminum rounds

entered in force the body and on which is threaded a silicone disc. These stops being placed on the trajectory of the small stem in

stainless drowned into the wing, the latter one cannot be inclined further.

This thrust system is only dimensioned to prevent the wings from being turned over. It was thus not possible to test a reduction of the amplitude of slope

of the wings.

cost :

Costing of the last prototype, by taking into account only the cost of materials :

8€ for 6 wings (420gr of resin) ;

9€ for 3 axes (33cm of tube) ;

2€ for the PVC body ;

3€ for the aluminum plate ;

2€ for the stainless screws, the thrusts... ;

TOTAL = 24€ /fin